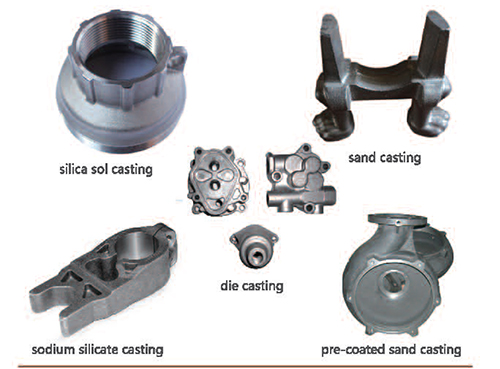

e offer high quality castings made from the following production methods:

- Sodium Silicate Process: Enables short lead time, good surface condition, and low cost. Suitable for carbon steel, alloy steel, stainless steel, grey iron, and ductile iron. Dimensional tolerance CT6-CT8

- Silica Sol Casting Process: Offers the best solution when dimensional precision is needed. Dimensional tolerance CT4-CT6

- Pre-coated Sand Casting Process: Alternative process to sodium silicate process but with higher production efficiency and lower cost. Dimensional tolerance CT6-CT8

- Sand Casting Process: The most commonly used casting process, especially for large castings. Suitable for almost any material. Dimensional tolerance CT8-CT10

- Die Casting Process: Tight tolerance and excellent surface quality. Commonly used for casting of non-ferrous metal. Dimensional tolerance CT4-CT6

Specifications

For carbon and alloy steel

- ASTM A27

- ASTM A216

- ASTM A148

- ASTM A487

- ASTM A217

- ASTM A389

- ASTM A297

- ASTM A351

- ASTM A560

For stainless steel

- ASTM A743

For ductile iron

- ASTM A536

For grey iron

- ASTM A48